SERIE 6000

HYBRID COMBINED CYCLE

Capacity: 33 to 300 tons

(99 to 900 GPM @ 95°F/85°F/78°F)

- Available in galvanized, galvanized with

epoxy coating for marine environments

and stainless steel - Low installation and operating costs

- Little noise and vibration

- Low power consumption per ton

- Easy maintenance

- Automated variable capacity system

by a programmable control panel

SERIES 6000 ADVANTAGES

Rotating-turbine nozzles vs. fixed-orifice stationary nozzles

The rotating-turbine (A) variable-flow sprinklers used for IM® towers provide a square, constant and uniform distribution pattern, irrespective of the flow of processed water.

Fixed orifice stationary sprinklers (B) provide uneven, conical dispersion patterns that create dry areas and water overload areas, which may change in response to variations in flow.

Twin wall

The interior flat wall in the packing area reduces “loss through the wall”, thereby increasing tower efficiency.

High-efficiency PVC laminate packing

Supported on the floor, with integrated drip and entrainment removers, which may be replaced without having to disassemble the tower.

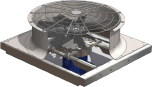

Low sound and vibration level

Independent, pressurized ventilation systems with high-efficiency and low-noise level FRP axle ventilators directly connected to low-speed TEFC electric motors.

Self-supporting structure

Hybrid structure (steel/FRP) does not need to be disassembled on a support beam structure, thus saving on installation costs.

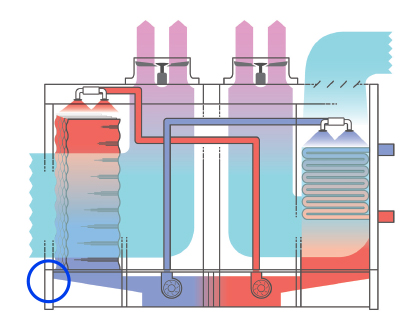

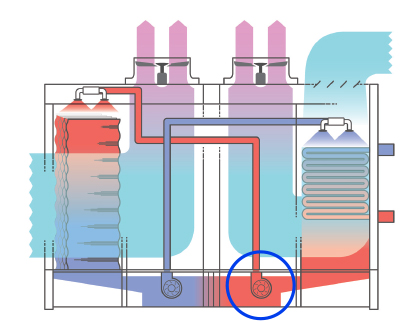

Pumping system

Independent cooling water pumping systems integrated into the machine.

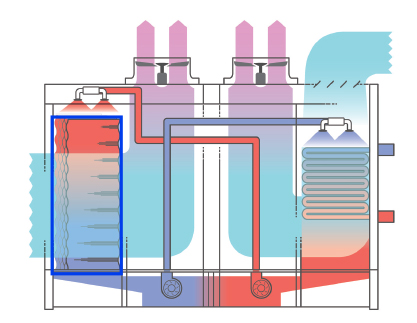

Sistema de serpentín

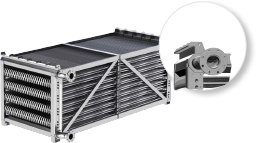

“Hung” on side rails and fluid connections in distributor heads. Configuration allows easy and quick extraction of the coil assembly for maintenance purposes. Assembly in models of the same group allows changing the size of the coil so as to increase or reduce machine capacity. Available in hot-galvanized steel or 304 or 316 stainless steel, both of which meet ASME B31.5 specifications. True parallel air/water flow on the coil, which eliminates dry areas and allows operation at a greater volume of air and water, without any increase in the system static pressure. At the same time it creates a ‘washing’ effect that prevents the formation of incrustation on the outer surface.

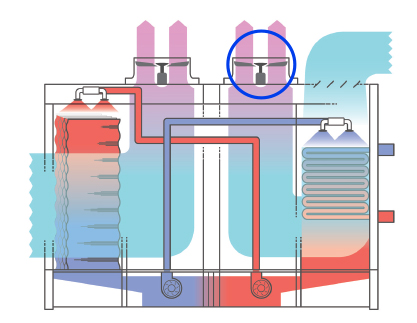

The modular ventilation system

The modular ventilation system has the facility to configure each section of the machine with 1, 2 or 3 ventilation modules, as needed to achieve the capacity required or to increase the capacity of an existing machine.

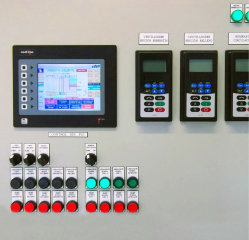

Variable-Capacity Automatic

Control System

The tower has the facility to be integrated into a system so as to operate at maximum efficiency. The system automatically detects failure of any system component and takes automatic action to change the equipment to the right failure operating mode.

The intelligent control software, completely developed by IM®, provides users

the facility to enter all control parame- ters so that the

machine may operate fully automatically at the highest possible

level of operating stability and energy efficiency.

All data are directly entered onto the terminal screen and the system

may also be connected to a central console or a

computer via Ethernet or TCP/IP.

The Control System includes all logical control and power

components required to operate all cooling tower elements and

the process fluid pumping system.

he touch control terminal (HMI) may be found on the front of the panel, together with all components for controlling the system in automatic, semiautomatic or manual mode in the event of PLC failure.

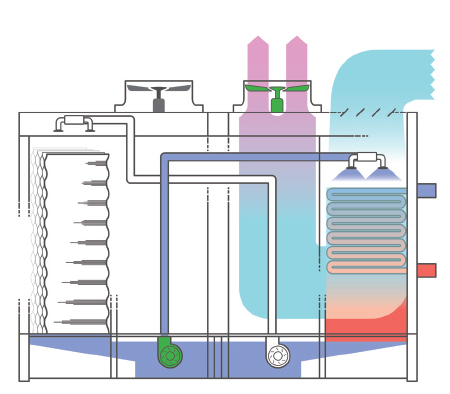

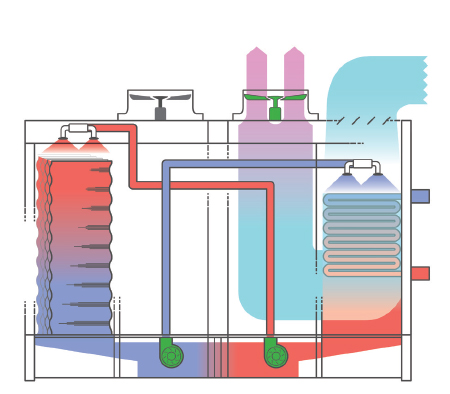

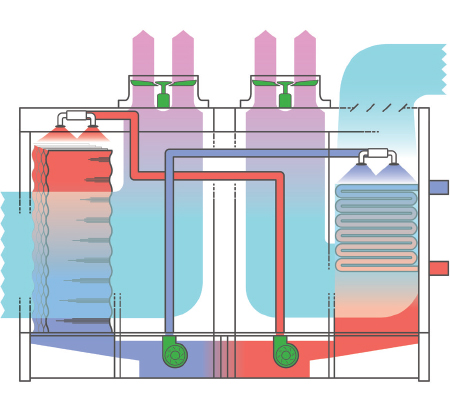

Operating Modes

The twin-section configuration of the IM6000 is unique in the industry and allows the machine to operate at greater process fluid outlet temperature stability. This tower is very versatile, as it may operate in several modes and at several capacity stages within each operating mode, thereby achieving high levels of energy efficiency, reducing use of evaporation water, thus substantially reducing operating costs.

Air only (variable flow) on the coil

Sensitive cooling/cooling water not used.

Air (variable flow) and water (fixed flow) on the coil

Indirect latent cooling / Uses some evaporation water.

Air (variable flow) and water (fixed flow) on coil and packing

Indirect latent cooling and hybrid cooling (sensitivelatent),

with no air induction.

Water (fixed flow) on the coil and packing, and air

(variable flow) on packing

Direct sensitive cooling and direct latent cooling

(evaporative) with induced air on packing

Air (variable flow) and water (fixed flow) on the coil and packing

Indirect latent cooling (evaporative) and direct

latent cooling (evaporative) wit induced air.

Why hybrid? See More

IM® 6000 towers use both thermal exchange processes: sensitive and latent. They may also operate with just air in the outer part of the coil, so the cooler operates at 100% sensitive cooling and does not use evaporation water.

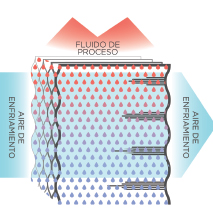

Sensitive Cooling

This is produced by the thermal exchange between hot liquid and cold liquid, without

there being a change in mass from one liquid to another.

When cooling hot liquid in indirect contact with a mass of moving gas, an interchange

takes place by convection due to the difference in temperature between the mass of the

liquid and the temperature of the gas. As there is no exchange of mass, there is no evaporation

of a part of the liquid, nor is there any increase in the relativity humidity of the mass of gas.

Latent Cooling (Evaporative)

This is produced by a simultaneous thermal/mass exchange that uses the energy required to

evaporate hot liquid (latent evaporation heat) and the difference of heat content between the

liquid and gas as the main motor of the cooling process.

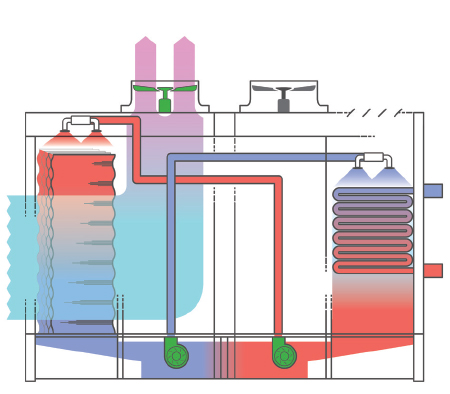

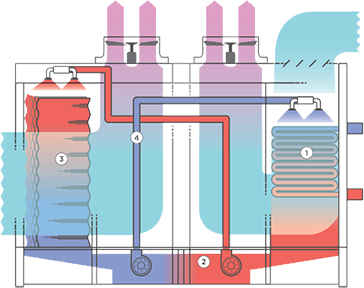

Single cycle VS. Hybrid combined cycle See More

Single Cycle

LOW ENERGY EFFICIENCY

1 The process fluid circulates within the coil and the cooling fluid, together with the airflow, circulates outside the coil.

All thermal energy to be dissipated passes from the processing fluid to the cooling fluid through the wall of the coil.

2 All thermal energy gained by the cooling fluid when passing outside the coil has to be dissipated into the atmosphere so that cooling fluid falls on the lower cooler tray at the same temperature as that at which it was originally sprayed on the coil.

System requirements: A high-power ventilation system that has the facility to move a large mass of air in a high-pressure drop ventilation system with which energy efficiency is very low, particularly when the systems operate at a wet-bulb temperature over 65°F or approaches close to 14°F.

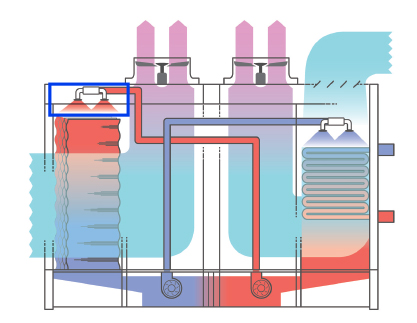

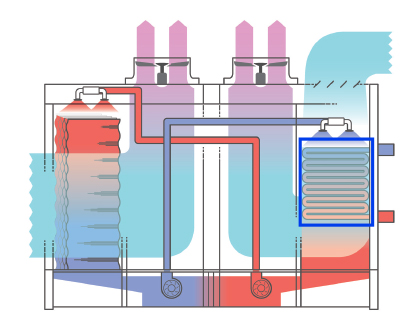

Hybrid Combined Cycle

ENERGY EFFICIENCY

Two thermal dissipation sections, one primary made up

of the single cycle as described above, plus a secondary

dissipation section.

3 Made up of a direct evaporative

exchange system in which the remaining thermal energy

is dissipated into the atmosphere before cooling water is

returned to the upper part of the primary section

4 System requirements: A much lower power ventilation system, as its aerodynamic system is much more efficient. This means its energy efficiency is much greater than the single system, in particular when operating at a wet-bulb temperature of more than 74°F or with approaches of less than 12°F.

The energy consumption of the single cycle is more than 200% of that required by the combined-cycle system.

Do you have doubts or would you like

Know more about the 6000 Series?

Let’s talk

In Mexico: 800 263 5300

Other countries: +52 (81) 1158-5300

Are you ready for

quote?

Please fill in the form data

And we will get in touch with you

To give you the quote.